Comco-PA 6 C

Polyamide 6 cast (PA 6/c) is a universal material for mechanical engineering applications. It features high mechanical strength combined with sufficient toughness and very good machinability. Its properties can be optimized for specific applications by adding other materials. The casting process allows for a wide range of shapes.

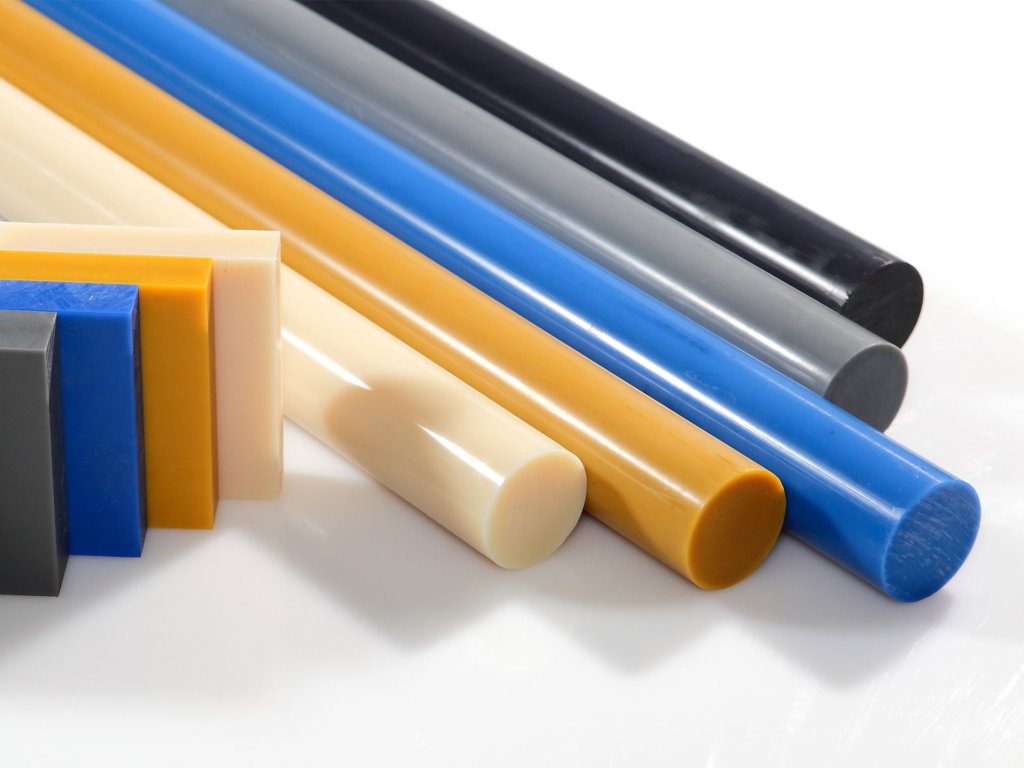

Colours: natural, black. Other colours on request

Characteristics:

- Excellent mechanical properties

- High chemical resistance

- High wear resistance

- Good machinability

Application areas:

- PA 6 C is used for various types of pulleys, bearings, rope sheaves and gear wheels.

- PA 6 C natural

- PA 6 C MO black

- PA 6 C colour

- PA 6 C Heat

- PA 6 C Wax

- PA 6 C Mod. / Powerglide

- PA 6 C HIGH IMPACT

- PA 6 C GLASS

- PA 6 C OL

- PA 6 C Moß2 anthracite

PA 6 C natural

Our premium-quality polyamide 6 cast in natural (ivory) with prompt availability. The universal material for general structural parts in plant and mechanical engineering. PA6C has very good antifriction properties and good resistance to gamma and X-rays.

Colour: natur

Round bars / Discs: Ø 50–2100 mm

Sheets (thicknesses): 10–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA 6 C MO black

This variant exhibits improved crystallisation and self-lubrication thanks to the addition of molybdenum sulphides. The hardness is increased and at the same time the general mechanical, frictional and wear behavior is improved. The material is produced in black.

Colour: black

Round bars / Discs: Ø 50–2100 mm

Sheets (thicknesses): 10–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA 6 C colour

Our premium-quality polyamide 6 cast specially dyed for your application. PA6C is available in red, yellow, green and blue. Further colours available on request.

Colours: red, yellow, green, blue

Round bars / Discs: Ø 100–2100 mm

Sheets (thicknesses): 20–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA 6 C Heat

Modified with a thermal-aging stabilizer, this material has excellent resistance to thermal influences under stress. The standard colour is blue.

Colour: blue

Round bars / Discs: Ø 100–2100 mm

Sheets (thicknesses): 20–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA 6 C Wax

The wax-modified polyamide 6 cast is characterised by better antifriction properties than the unfilled type. Applications include sliding elements and guide pieces, as well as sliding strips of all kinds. PA6C WAX is available in gray.

Colour: gray

Round bars / Discs: Ø 100–2100 mm

Sheets (thicknesses): 20–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA 6 C Mod. / Powerglide

This modified polyamide type was specially developed for structural parts where antifriction and wear properties are extremely important to ensure reliable operation over an extended period. Compared to metal, this construction material is characterised by lower weight. Powerglide also has better tribological properties than unfilled plastics. If the antifriction properties of PE 1000 are required, as well as the superior wear resistance and high mechanical strength of polyamide, Powerglide is the ideal material. Applications include sliding and bearing elements, wear strips and heavy-duty pulleys in all areas of mechanical engineering, crane construction and conveyor technology. Curve guides, toothed and sprocket wheels are further examples of applications. Powerglide is available in green as standard, and in other colours upon request.

Colour: green

Round bars / Discs: Ø 50–2100 mm

Sheets (thicknesses): 10–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA 6 C HIGH IMPACT

This ployamide, which is also produced by the pressureless casting process, is a blended product based on caprolactam (the raw material for PA6C) and Laurinlactam (the raw material for PA12C). Compared to pure PA6C, the material has a lower water absorption and higher toughness. Applications include gear wheels, inlet and outlet star wheels or track rollers. PA6C HIGH IMPACT is available in natural / yellowish colours.

Colours: natural / yellow

Round bars / Discs: Ø 100–2100 mm

Sheets (thicknesses): 20–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA 6 C GLASS

This type, filled with glass beads, has a higher dimensional stability, higher stiffness and lower water absorption. It also withstands higher service temperatures. The standard glass ball content is 30%, but customer-specific proportions can also be produced. Applications include heavy-duty mechanical engineering elements, tension rollers, coupling flanges, curved sections and guide elements. PA6C GLASS is available in natural colour / gray.

Colours: natural / gray

Round bars / Discs: Ø 100–2100 mm

Sheets (thicknesses): 20–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: on request

PA 6 C OL

PA6C OL is modified with an incorporated liquid lubricant, which is distributed in the material in microscopically small droplets. This material is ideal when the stick-slip effect is to be improved. This material is perfectly suited for slow-moving, dry running sliding elements. Applications include bearing bushings, guides and curve guides. PA6C OL is available in yellow and black as standard, and in other colours on request.

Colours: yellow, black

Round bars / Discs: Ø 50–2100 mm

Sheets (thicknesses): 10–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

PA6C Moß2 anthracite

PA6C Moß2 is modified by the addition of molybdenum disulfide (Moß2). The hardness is increased and at the same time the general mechanical properties and the friction and wear behavior are improved. The material is produced in the color anthracite.

Colours: anthracite

Round bars / Discs: Ø 50–2100 mm

Sheets (thicknesses): 10–100 mm

Blocks (thicknesses): 110–500 mm

Tubes / Rings: OD Ø 50–2100 mm

- Products

- Thermoplastic semi-finished products

- Comco-PA 6 C